Collet Chuck

Overview

|

Images courtesy of Beall Tool Company |

A Collet Chuck is particularly useful when an object is transferred between lathes. For example, a part can be started on a "traditional" lathe, held in a collet, and then moved to the rose engine lathe which can also hold the object in a collet. The use of collets to hold objects minimizes the error (runout) with moving to a new lathe.

For example, you can shape an object such as a shaving brush on your "traditional" lathe to the point where you can hold it in a collet. Finish the object there, including all the finish sanding.

- A "traditional" lathe has a 11/4" - 8 thread on the drive, and you will need a collet chuck for that size threads.

- The Beall I-X Collets are held in a 1/2" collet. The other end is selected based on the object you wish to hold.

Now the ornamental turning can be done on the rose engine lathe by moving the object to that lathe. If you are using an I-X collet, then keep the object on the I-X collet.

- A typical rose engine lathe has a 1" - 8 thread on the drive, and you will need a separate collet chuck for that size threads.

One ornamental turner with whom I spoke is working towards putting collet chucks on all his lathes (he has many). Then, he will be adding a stub to his traditional woodworking chuck, replacing the typical threaded mount. The traditional chuck would then be held by the collet chuck in whichever lathe he was using. This would minimize the runout when moving the object from lathe to lathe, whilst also not taking it from the chuck. (Note, for this, he is looking to use the bigger ER-50 chuck rather than the smaller ER-32 chuck.)

Some ornamental turners dispute the value of these. Their argument is that the runout experienced in moving objects between lathes is in the drive threads (onto which the collet is screwed). They argue that the more accurate means for transferring an object is to hold it in the Morse taper (or use a collet holder as the spindle for your rose engine lathe -- this is what Ed French does).

Examples of this device in use

Recently, I chose Osage Orange for the knob on the lid of a Beads of Courage box as it worked well with the other colors. The knob is designed to be held to the lid by a tenon. That tenon was not a size that accommodated using any of the scroll chuck jaws I have, so I made a wooden collet.

The wooden collet I used (shown to the left) served two purposes: Firstly, it facilitated easily holding the knob for the ornamental turning.

But these jaws also allowed for easily cutting on the bottom part of the knob. This is key as it allowed the rose engine's horizontal cutting frame to have the clearance needed, and to avoid the cutter hitting the chuck's metal jaws.

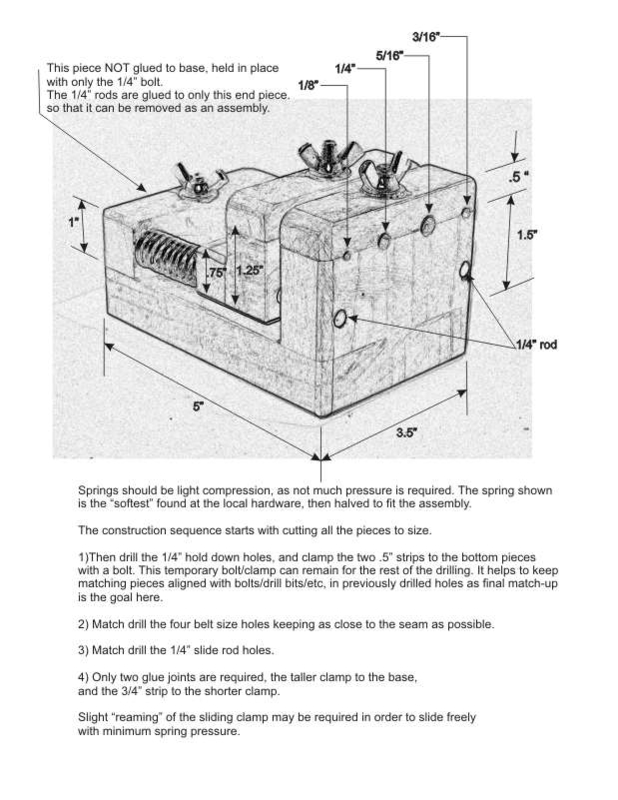

Notes on making one

Wooden collets, based on Colin Hovland's article, Wooden Collets for a Scroll Chuck, are a great option if you are considering the value of using collets. I have made a number of such collets for work holding in a similar approach.

More Information

Published Articles

- Introduction to Collets by David Lindow. LW Rose Engine News, Volume 2, No. 2 - Autumn-Winter, 2011, pg. 11

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |