Cross Slide

Overview

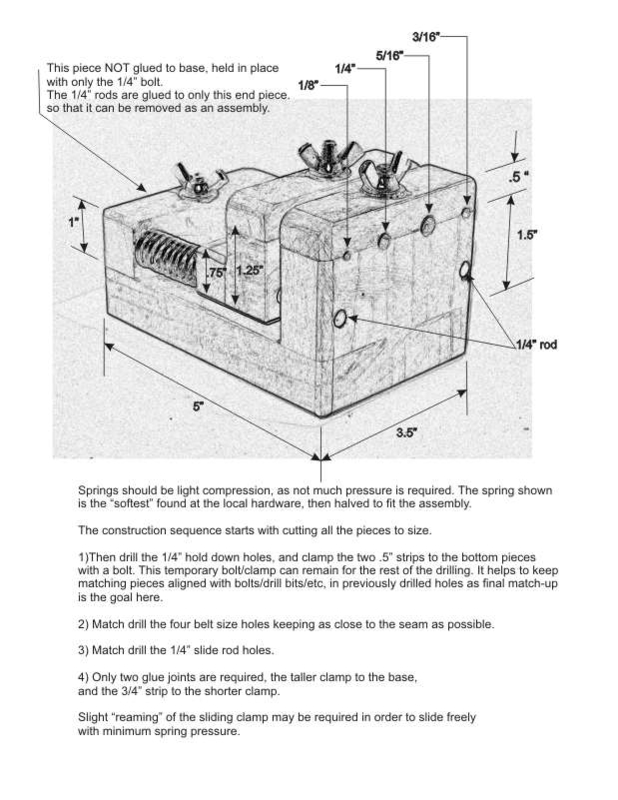

Hardinge Cross Slide

To get the cutting frame or Drill Spindle in the right position for cutting, it is held in a quick change tool post bolted to a cross slide (sometimes called a "table" or an X-Z Table).

All metal lathes have a cross slide built into the bed of the lathe (these usually have a compound slide added). Wood lathes don't have a cross slide; instead they have a fixed tool rest.

Milling machines also have cross slides as an integral part. In both cases, the cross slide allows very precise alignment of the cutting tool with the object being formed.

In some applications (e.g., milling), the cross slide would be called an X-Y table, but when used on a lathe, the directions are as diagrammed in the drawing on the lower right, "Lathe Axes". This is because the part being turned on the lathe would be on its side (so the cross slide is sometimes called an X-Z table).

Lathe Axes

- X axis - used to denote movements perpendicular to the axis of turning, and on the horizontal plane.

- These movements are made using the Cross Slide.

- Y axis - used to denote movements perpendicular to the axis of turning, and on the vertical plane.

- Movements in this direction are made using the quick change tool post, but really these movements are only to change the way the tool engages with the object.

- Generally, the tool is aligned so that the cutting edge is at the exact center of the object (especially when working on the end of the object).

- Z axis - moving towards, or away from, the headstock of the lathe. These movements are along the axis of turning.

- These movements are made using the Cross Slide.

Cross Slide

Image courtesy of

LittleMachineShop.com

The quality of a cross slide can vary greatly, and the better the quality, the higher the cost (we all know the old adage, "you get what you pay for"). The Hardinge cross slide is very well built and works greatly, but that comes at a high cost. You can find a used Hardinge cross slide, and the used ones are potentially a good value. In 2018, one that is in good shape was in the $2,500 range.

With a typical cross slide, the top slide is locked at a right angle (90°) to the bottom slide. The top slide moves along the X axis, the bottom slide along the Z axis. The Hardinge slide allows the user to adjust this relationship. The top slide can be rotated relative to the bottom slide. (On a metal lathe, this is accomplished by a 3rd slide above the bottom two.)

There are some operations where this rotation may be useful. One ornamental turner told me he used it for a cutting operation that was not achievable otherwise. But, you can start with the one shown at the right, and upgrade to the Hardinge later.

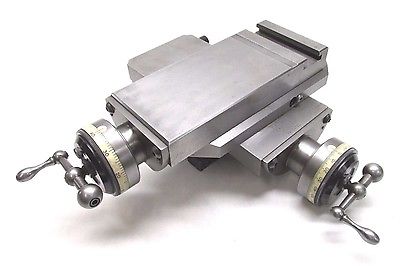

A good source for buying a decent, beginner-level cross slide for the person getting started (and a quick change tool post) is LittleMachineShop.com. A starter-level cross slide is :

- Part number 2008 - X-Y Table Assembly

This is the one shown above on the right.

The tool being held in the cross slide receives downward force from the pressure the object's rotation places on the cutting tool. However, when using a cutting frame or a Drill Spindle in ornamental turning, the cross slide does not receive as much pressure as it would when using fixed tools or on metal lathes. Thusly, the cross slides on starter-level ornamental lathes do not have to be as rugged, and usually have a larger range of movement in the Z axis.

Notes on working on one

Adjustable Pin Spanner Tool Set

Hardinge Compound Cross Slide

Some cross sides need a pin spanner to remove parts. For example, the parts noted with red arrows on the Hardinge compound cross slide shown to the left need such a tool to remove.

Stupid Simple Tools makes the set shown to the right. This allows for the correctly sized pin to be used (either metric or imperial sized), and makes the operation quite simpler. The noted tool set is available from Amazon for a reasonable price.

Snap ring pliers with replaceable tips may seem like a good option but the pin spanner is a far better solution as the snap ring pliers will probably damage the part.

There are also some great articles and presentations noted below which are worth considering.

Sources for buying one

More Information

Published Articles

- Aligning the Hardinge Slide Rest On A L-W Rose Engine by Brian Clarry. LW Rose Engine News, Volume 2, No. 1 - Spring-Summer, 2011, pg. 4

- Lindow Rose Engine Alignment Procedures, Section 4, pg. 1

- Slide Rest Construction Project: Engine Turning with a Cross Slide, by Steve White.Ornamental Turners International Newsletter, Volume 19, No. 1 - Spring, 2012, pg. 7

Presentations

- Fine tuning the cross slide is recommended, especially if you opt for a starter-level one. This video, Lathe Adjustments - Fine Tuning, outlines how to do this on a hobbyist metal lathe, and the approach works well for this cross slide also. These instructions are worth following.

- This video, Hardinge Cross Slide - Care & Adjustments, is about refurbishing and fine tuning the Hardinge cross slide. It was given by David Lindow at the 2018 Ornamental Turners International Symposium.

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |